Success Stories

Data Elements: SuccessStories.aspx

Filter Success Stories By

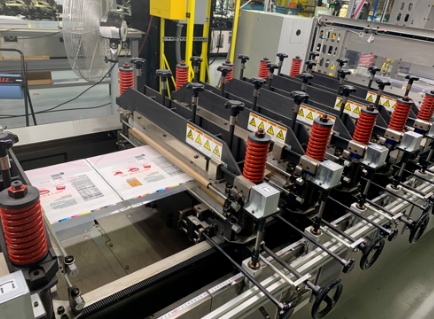

Flexible Packaging Facility Achieves Highest Food Safety Certification

Company Profile

Portco Packaging is a flexible packaging solution manufacturer for the food, agriculture, construction and retail markets. The company is located in Woodland, Washington and has 50 employees.

Situation

Company leaders wanted Portco to obtain the Safe Quality Foods (SQF) certification to increase its competitive advantage in the food processing packaging arena. They also wanted to implement Lean Training and Lean Manufacturing strategies to increase efficiencies and accelerate lead time for important regional companies. The company reached out to Impact Washington a NIST MEP affiliate, for high quality consulting and technical assistance at an affordable cost. Because Impact Washington was locally based, Portco avoided travel expenses and gained access to workforce (JSP) training funds through a partnership with Lower Columbia Community College, the local community college.

Solution

Impact Washington encouraged Portco to seek Level 3 certification in SQF. With over 20 years in the food processing business, IW consultant Bill Paugh coached and aided the company in preparing for Level 3 SQF audit. During this time, the company made changes to the plant layout and implemented several Lean Manufacturing process improvements. Impact Washington trained a select group of Portco employees to become internal Lean Champions through the Lean Enterprise Certificate Program, and led a Training Within Industry Job Instructions training to better cross-train and develop employees’ capabilities to advance.

Portco successfully passed the SQF audit at a rating that even many food processors fail to achieve initially, becoming the first flexible packaging company on the West Coast to achieve the highest level of food and quality certification from an internationally recognized standard. The improvements helped the company reduce customer returns, inventory turns, scrap and rework. It increased production capacity, added new jobs and and won new business. “This has opened doors and I believe it will help to shorten our sales cycle,” said Kent Wall, company president. “We did not achieve every goal we aimed for a year ago but we are well on our way to meeting and exceeding them in the near future.”

Results

- Successfully passed the SQF audit

- Reduce customer returns, inventory turns, scrap and rework

- Increased production capacity

- Added new jobs and

- Won new business.

"We have already begun to realize positive market growth in our food packaging offerings and have obtained new accounts due to our SQF level 3 certification. My philosophy is that for Portco to succeed in an ever more competitive world marketplace we must continually invest in new technology and most importantly we must invest in our people." - Kent Wall President / Portco Packaging