Recovery and Reopening

COVID-19 Response Operational Guidelines for Manufacturing Facilities posted to the Governor’s website on May 12, 2020

Please note: Previously authorized manufacturing operations must implement all requirements under Phase 2, Manufacturing Facility COVID-19 Requirements by May 27, 2020, or may operate under a separately approved plan by the Department of Labor and Industries - see memo from Governor Jay Inslee dated May 12, 2020

No-Cost Preventative & Preparedness Assessment

As the state’s COVID-19 curve continues to flatten, Impact Washington has begun providing no-cost readiness assessments to help businesses prepare to return to work. Using funds authorized by the CARES Act signed by the President in April, NIST issued awards to Manufacturing Extension Partnership (MEP) centers for COVID-19-related projects. The first authorized usage of our funds is going towards Prevention and Preparedness. Additional fund phases will support the operational needs of manufactures related to COVID-19 Recovery Projects.

The Assessment includes a virtual site visit with an Impact Washington consultant followed quickly by a thoughtful implementation plan and debrief to ensure a smooth restart of your business as soon as possible. We are relying heavily on OSHA guidance, sound manufacturing principles, and assistance from HR professionals when conducting these reviews. The potential for close contact can occur in so many environments – including packaging areas, production lines, locker rooms, restrooms, etc. – and these assessments address those environments and more.

To get your facility on our assessment schedule, contact Impact Washington HERE or call 425-438-1146.

Please download our Guidance Whitepaper on Preventive Measures & Controls. You can also view the following 45-minute video for an overview of the assessment

View our COVID-19 Business Recovery Event Schedule to learn about a Return to Work Webinar in your area or listen to previous recorded Webinars

The completed assessment will summarize and document individual risk levels found within each facility and provide recommendations for specific workplace controls. In manufacturing environments, the potential for close contact can occur on or near production lines, receiving and packaging areas, sampling and quality rooms, and in common facility areas such as conference rooms, lunchrooms, locker rooms, restrooms, hallways, and entryways.

Why Workplace Measures are Important:

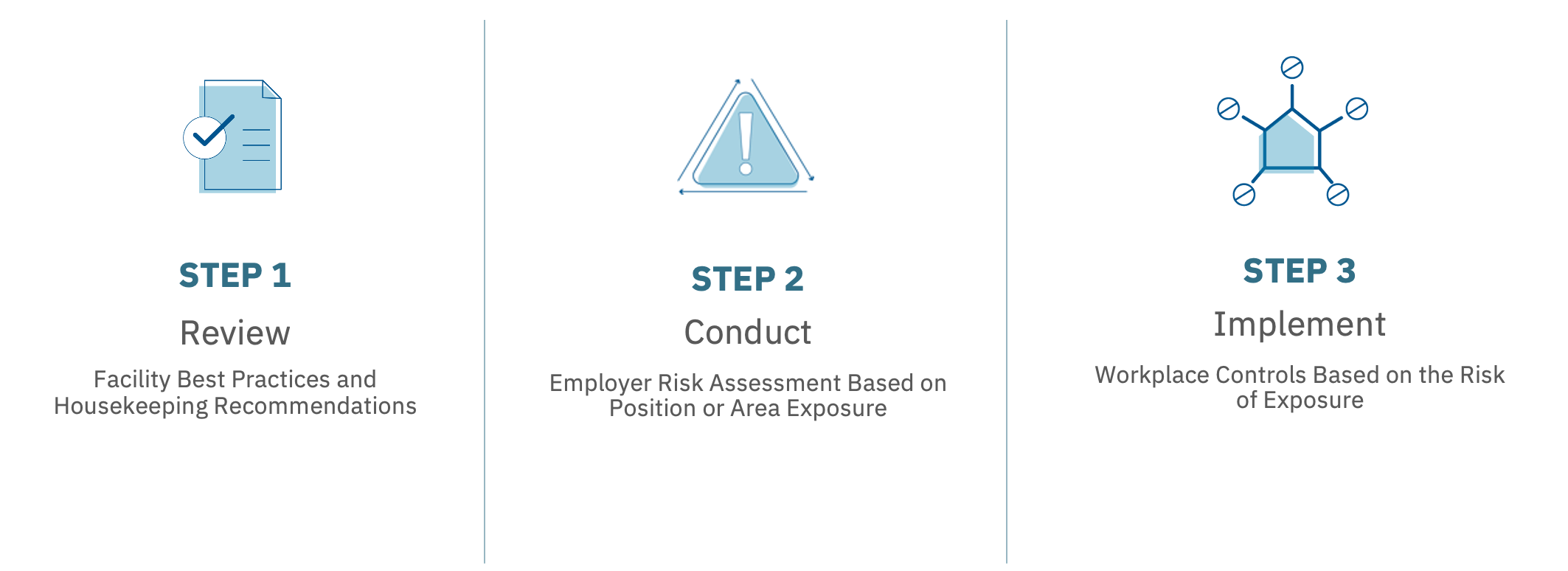

In order to manage COVID-19 risks for employees, it is critical for manufacturing facilities to review their policies and procedures relative to current knowledge of the risks. The following guidance is based on our current understanding of the virus and designed to help companies review and amend their policies.

Ultimately, each facility will need to implement policies tailored to their specific facilities and any risks relevant to their employees or those that they may encounter during work time. Social distancing by staying six feet away from others is considered a workplace best practice with a strong recommendation to make the most of telecommuting options for as many employees as possible.

Additionally, employers should conduct a Risk Assessment of their facilities to determine whether Engineering Controls, Administrative Controls, or Personal Protective measures are recommended based on the work areas within their facility or each employees risk of exposure due to the nature of their job functions.

High-Level Steps For Site Compliance